Dive Theory Equipment

DOM GIBBINGS

Dive Theory: Equipment

Once you have followed our study guidelines, use these Revision guides to help you memorise the required knowledge for your IDC & IE dive theory exams.

Tanks

Scuba Cylinders

Cylinder = Tank = Bottle = very strong container with an on/off valve to control the flow of the gas.

Steel Tanks

- First kind of tanks & favorite for tec dive

- Hard (therefore, resistant to external damage)

- Negatively buoyant even empty

- The highest capacity cylinders are steel

- Drawback of steel = without proper care, rust may form

Aluminium Tanks

- Softer (more susceptible to damage from impact)

- Thicker walls

- Positively buoyant inside the water.

- Doesn’t tolerate overfilling (over-pressurizing) as well as steel

- Dominate recreational diving thanks to it resistance to corrosion

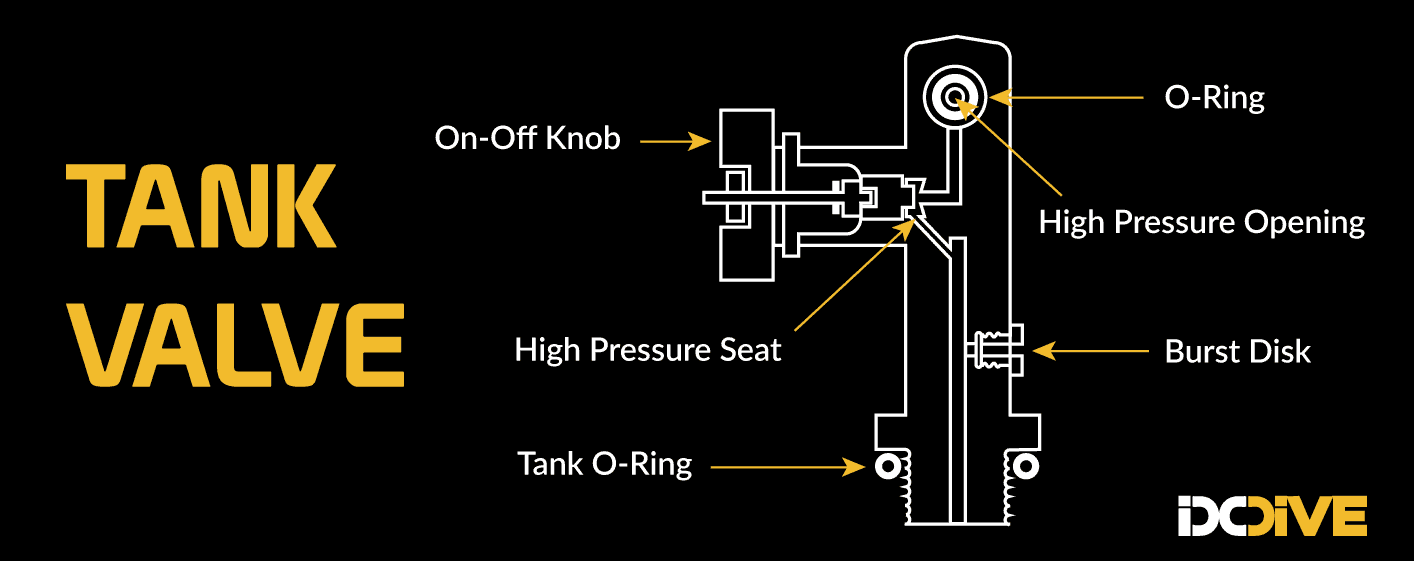

Valves

K VALVE = Simple on/off valve. By far the most commonly used.

J VALVE = A valve with a mechanical reserve.Contains a spring-loaded mechanism that, when activated (placing it in the “up” position), restricts the air flow when the pressure drops to between 20-40 bar. This alerts the diver to low air. The diver pulls the lever to the “down” position, which releases the restricted air flow. Extremely rare now days.

Valves Systems

YOKE = International System, the regulator clamps over the valve

DIN = (Deutsche Industrie Norm), the sealing o-ring mounts in the regulator, which screws into the valve. “DIN screws in”

More Features

BURST DISK = Protects against damage that may occur from accidental overfilling, but more often from accidental overheating.

If cylinder pressure rises to approx. 140% of the working pressure, the disk ruptures and the air escapes through the vented plug. Downside is that they have to be replaced periodically.

O-RINGS = Little rubber rings, which use the gas pressure to form a tight, reliable seal.

Tank Inspections

Visual Inspection

A visual inspection is required by international law to be conducted on all tanks (steel and aluminium) once (1) a year.

A visual inspection is conducted by removing the tank valve and looking inside for any corrosion (steel tanks = rust / aluminium tanks = aluminium oxide). If there is any corrosion the tanks will be machined and chemically cleaned. If the corrosion has done damage to the wall of the tank the tank will be condemned.

The threading at the neck of the tank (where the tank valve screws in) is also inspected for any damage.

Pressure (Hydrostatic) Test

Hydrostatic inspection = water pressure test

Laws differ from country to country (US = 5 five years, UK = every four 4 years)

A hydrostatic test is performed to ensure the tank has no weak points in the body, and to make sure that the tank can withstand acceptable high-pressure air used for diving.

- A hydrostatic inspection is conducted by placing the tank in a container filled with water.

- The tank is then filled with water, which will be used to pressurize the tank to approximately 7/5 of its working pressure.

- Afterwards the tank is checked for any damage or disfigurement (shape change) that may have occurred during the test.

Certain circumstances can weaken tanks before a hydrostatic test is required. Have tanks hydrostatically tested after exposure to any of the following:

- Tumbling (or sandblasting) to remove corrosion

- Damage due to impact

- Exposure to heat in excess of 82º C may affect the metal’s integrity. Never paint a cylinder using a heat painting process such as that used on automobiles

- If left unused for more than 2 years

Tank Markings

Tank Markings

Government Agency Supervision Approval

DOT/CTC (Department of Transportation, Canadian Transportation Commission)

Metal Type

3AA = Steel

3AL, SP6498, E6498 =Aluminum

Working Pressures

Maximum pressure lbs/inch2 (steel = 3000-4000; aluminum = 2250)

Serial Number= Unique for each tank (in the example =12345)

Manufacturer= PST, Luxfer, Kidde

Hydrostatic Test = month ♢ year

10% Overfill Allowed “+” = 10% overfill allowed on Steel Tanks

Regulators

Regulators

Regulators = demand valves = deliver air at a pressure that’s about the same as ambient pressure.

Two stage single hose model regulator is the only model used widely by recreational divers today. Reduce the cylinder pressure to breathing pressure in 2 steps (first and second stage)

Open Circuit Scuba

Typically used by recreational divers. The diver inhales air from the cylinder via a demand valve regulator and exhales it into the water, thus the circuit is open because none of the air is recycled.

Though open circuit doesn’t recycle breathing gases, it is the main stay of recreational diving for several reasons.

- It’s a much simpler design, which makes it reliable and less costly (closed and semi-closed systems are more prone to malfunctions)

- It requires only a cylinder of air (closed and semi-closed units require chemicals and access to pure gases or enriched air)

- It is much easier to use

- It is much simpler to maintain and service.

Semi-closed Circuit Scuba

The diver inhales from a breathing bag that receives a steady flow of gas (usually enriched air).

The diver exhales back into the breathing bag and the gas has carbon dioxide removed chemically – excess gas from the steady flow trickles out through a valve.

The circuit is semi-open because part of the gas is recycled and part of it is released (except to vent expanding air on ascent)

Closed Circuit Scuba

The diver inhales from a breathing bag and then exhales back into the breathing bag.

The gas has carbon dioxide removed chemically and electronic sensors control the flow of oxygen and other gases as required.

The circuit is closed because all gas is recycled and none is released (except to vent expanding air on ascent)

Regulator: First Stage

First Stage

First Stage = reduces the high pressure delivered by the tank to an intermediate pressure (usually about 10-13 bar above the ambient water pressure).

When the diver inhales, the air pressure in the first stage drops below the desired ambient pressure. This allows water pressure to flex a diaphragm or move a piston, opening a valve that releases air from the tank. Air flows as long as the diver inhales, keeping the first stage from reaching intermediate pressure. When the diver stops inhaling, the pressure rises in the first stage so that upon reaching intermediate pressure, the valve to the tank closes and air no longer flows.

Balanced / Unbalanced

UNBALANCED

A regulator designed so that tank air pressure resists or assists the opening of valves in the first stage is called an unbalanced regulator.

- Less costly design

- Breathing characteristics change with cylinder pressure

- No longer commonly found

BALANCED

A regulator designed so that tank air pressure neither assists or resists the opening of valves is called a balanced regulator.

- Breathing characteristics unchanged with varying cylinder pressure.

- Virtually all modern regulators are balanced regulators.

Environmental Sealing

To avoid freeflow in extremely cold water, some regulator first stages have environmental sealing. This seals silicone grease or oil, which doesn’t freeze, around the first stage. The silicone or oil transmits the pressure from the water to the diaphragm or piston so the regulator operates normally.

Regulator: Second Stage

Second Stage

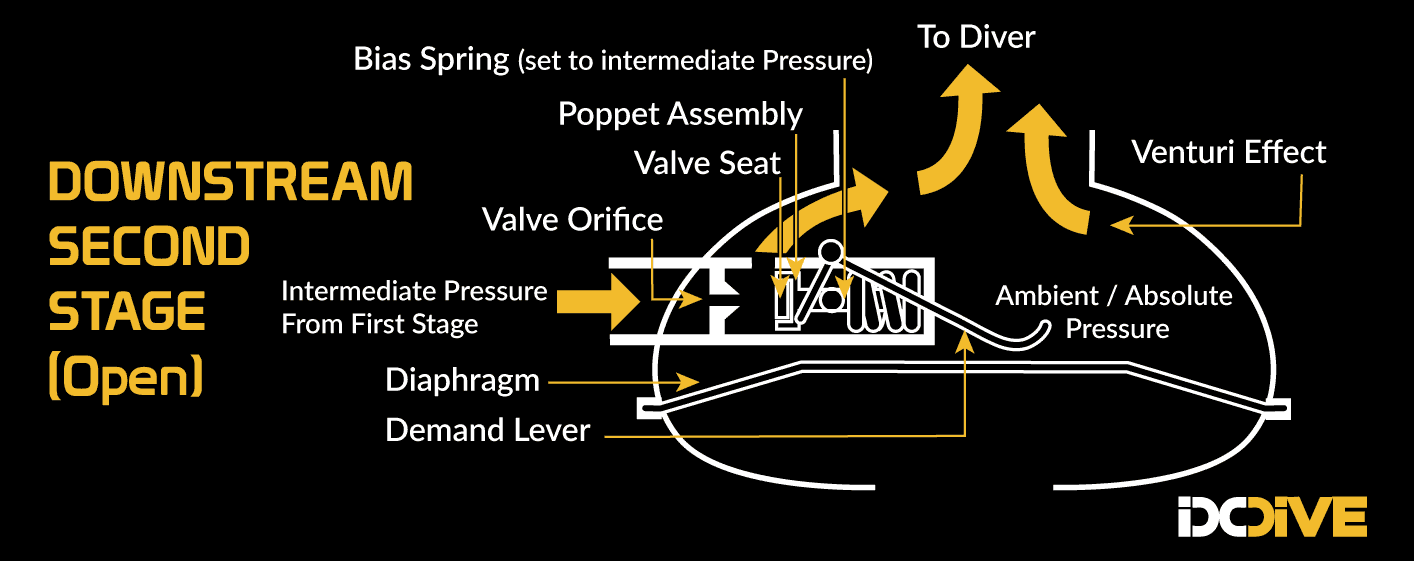

SECOND STAGE = reduces the intermediate air pressure to ambient pressure for breathing. When the diver inhales, water pressure pushes in a diaphragm in the second stage and opens the second stage downstream valve releasing air flow from the first stage. As long as the diver inhales, air continues to flow. When the diver stops inhaling, the diaphragm returns to its relaxed position and the valve closes. Exhaled air exits the second stage through oneway exhalation valves.

Valves

DOWNSTREAM VALVES

(Modern open circuit regulator valves design) they open with the air flow (the pressure is trying to open the valve) rather than upstream, in which the valves open against the air flow (the pressure is trying to close the valve). A malfunctioning downstream valve will permit continuous air flow (freeflow) rather than cut off air flow.

PILOT VALVE

On some second stage models, the diaphragm opens a small pilot valve, which creates a pressure imbalance that opens the main valve.

- Advantage – less breathing effort

- Disadvantage – more complex design difficult to service and adjust.

Freeflowing

Regulators fail-safe design = a second stage would fail in a safe manner, in which it continues to provide air. Obviously the tank will exhaust quickly so the diver must ascend immediately.

Instruments

Depth Gauges

CAPILLARY GAUGES

Capillary depth gauges are a simple piece of clear tubing, sealed at one end and open at the other, with depth increments indicated according to where the water column rests based on Boyle’s Law. They are inexpensive and reliable, though hard to read accurately much deeper than 10 meters/ 30 feet.

OPEN BOURDON TUBE GAUGES

Open bourdon tube gauges contain a spiral shaped tube. Water enters the tube end and increasing pressure causes tube to straighten somewhat. The straightening moves the depth gauge needle. Because the tube is open, clogging can be a problem with these devices.

OIL FILLED GAUGES

Oil-filled gauges also use bourdon tube design, but using a sealed tube in an oil-filled gauge housing. Pressure transmitted through the oil causes the tube to coil more tightly. This moves the depth gauge needle. The depth gauge is not open to the water and therefore not clog prone.

DIAPHRAM GAUGES

Diaphragm gauges function by connecting a flexible diaphragm to a series of levers and gears that move the display needle.

DIGITAL GAUGES

Digital gauges are electronic gauges that read depth via a transducer, which varies the electricity it transmits depending on the pressure exerted on it. These provide a digital display. These offer the highest degree of accuracy, and are used in dive computers to determine depth.

Compasses

North needle of compass always points to magnetic north because the needle is a magnet, aligned by the field of earth’s geomagnetism. With most dive compasses, the diver reads direction directly against the needle, but new electronic compasses read the heading digitally. Divers use liquid filled compasses so the gauge withstands pressure, and to dampen needle movement for easier reading.

SPG

SUBMERSIBLE PRESSURE GAUGE (SPG)

SPG = tells you how much air you have left, making it indispensable for safe diving.

The SPG works based on the same principle as the bourdon tube gauge – high pressure air from the cylinder enters a C shaped or spiral tube and causes it to straighten somewhat, causing the SPG needle to read the pressure. Electronic SPGs use a pressure transducer similar to those in dive computers/electronic depth gauges.

SPGs may be integrated with dive computers. The most recent innovation is a transducer on the regulator that transmits the air pressure to a wrist-worn computer, eliminating the SPG hose.

Enriched Air Nitrox & Oxygen Equipment Considerations

Equipment

As oxygen content rises, substances combust or burn more readily. Materials such as neoprene rubber, lubricants (silicone grease) and contaminant (dust particles) may theoretically pose a hazard with enriched air.

- If a piece of equipment won’t be exposed to more than 40% oxygen, standard air equipment is fine

- If a piece of equipment will come in contact with more than 40% oxygen, then it must meet oxygen service standards

Tanks

The cylinders for Nitrox need to meet oxygen service standards even if you won’t be using EANx40. One method of blending air is filling the oxygen first, then adding air until ending up with the desired % of oxygen and nitrogen. The cylinder will be exposed to high percent of oxygen during blending.

EANx Distintive Markings

IDENTIFICATION BAND: 15 cm wide band with a 2.5 cm yellow band at the top and at the bottom and the center area in green. In the green area must be written “Enriched Air”, “Enriched Air Nitrox”, “Nitrox” or similar in yellow letters.

A yellow cylinder requires only the green portion of the band with the yellow letters.

LABELS or TAGS: state the cylinder oxygen content, the fill date, the analyzer’s name, the diver’s name and the maximum depth at which the blend can be used.

VISUAL INSPECTION STICKER: noting that the cylinder has been serviced specifically for use with enriched air and whether it does or does not meet oxygen service standards.

OXYGEN – the cylinder should be entirely white or yellow with a large label that reads “Oxygen”

⎮ Privacy Notice ⎮ Cookies Policy ⎮ Sitemap ⎮ © IDC DIVE 2018, Powered by Katuak